I first used Borosilicate glass plates that came with the machine. I am printing in ABS so the glass needed to be at 110 degree C.

They lasted for only a few prints and then chipped like crazy.

I tried a multitude of attempts to prevent chipping. I cleaned the glass with Acetone, used only a little bit of Aquanet hair spray, all sorts of tests. I went through 2 sheets of glass until I figured out that this was crazy.

Maybe the glass is made in China and if so that's probably part of the problem.

I work with aircraft fabrication and found a piece of 1/8" aluminium laying around the shop. This size is almost exact to the thickness of the 3 mm glass so no modifications to the bed are necessary.

Couple of caveats however. Aluminium is metal and conducts electricity and I'm installing it on a PC hot bed. Just in case any of the traces may be bare, I put a piece of parchment paper under the aluminium pate. On the led end I put a piece of kapton tape over the led and the open PC board traces.

I searched the Internet and found 3D-eez. Amazing stuff. I spread it on the surface as per the instructions and it worked out well. So good was the adhesion that I couldn't get my print off the plate. I froze it, heated it and to no avail. Back to the drawing board.

OK, then I told the slicer to print a raft, and wow what a difference. I can now say I am getting great print results.

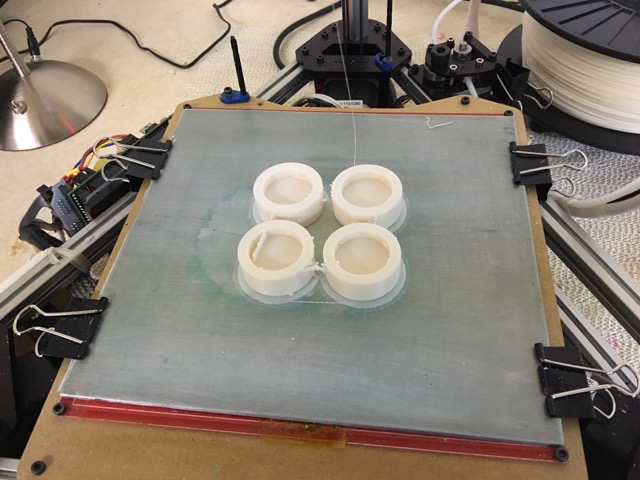

Here is the final hot bed setup after printing 4 replacement patio chair feet.

I also cut out another aluminum plate, so I can take a print off the printer and then start printing again right away.

I still had the curling problem on long flat prints, so I wrapped cellophane around the bottom of the printer rails. The result was a great improvement. Now to design and build an enclosure for the printer.