Wiring Techniques

To solder or not to solder wire connections ?

In my opinion, your life may depend on good wire connections. Never ever use butt connectors as shown above in your airplane. I was troubleshooting a problem in a Mooney and found 5 butt connectors in about 1 foot of wire. This is very bad practise. If you see your mechanic using them, fire him !

This is the proper method. Strip the ends about 3/4" back, twist each wire then twist them together.

For a complete tutorial see this Instructables Tutorial

To solder or not to solder crimped connections ?

- Argument: Many hangar experts claim that Boeing does not solder any wires or terminal they only crimp them. This is well and good however, the theory being that by properly crimping you can remove a lot of the oxygen from the connection to prevent corrosion.

Response: Yes it can be done with special terminals lugs and $250.00 crimpers which in a sense cold welds the terminal. Don't ever think you can get the same result from hardware store crimper and terminals.

If we use the standard crimpers the stranded ends of the wires are still exposed and moisture will wick up into the wire and eventually corrode the terminal.

- Argument: When you solder a crimped connection you harden the wire where it enters the crimp and through movement eventually it will break off.

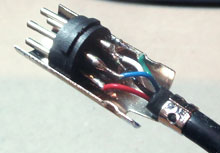

Response: So then all we need to do then is to provide a strain relief so the wire can't wiggle. The same thing we do when we solder wires on the pins in a jack. The wires coming out of the jack are secured to the case as shown here.

Do you see anything missing from this solder job ? No, how about the fact that there is no shrink wrap on all the pins, even though it has a metal shield. Bad practise ?

There are many other methods of crimping with a whole slew of different crimpers and terminals. I am just covering the types that we generally use on our airplanes.

| Types of Crimp Terminals | ||

|

|

|

| Spade Terminal | Loop Terminal | Loop terminal Uninsulated |

The spade type should never be used in your airplane. They will vibrate loose and fall off the terminal and break the connection.

The next type is the loop terminal with an insulator included.

The 3d type is a loop terminal without the insulator.

| Types of Crimpers | |

|

|

|

|

| This one squashes the Insulator Type Terminal | This one dimples the Un-Insulated Terminal |

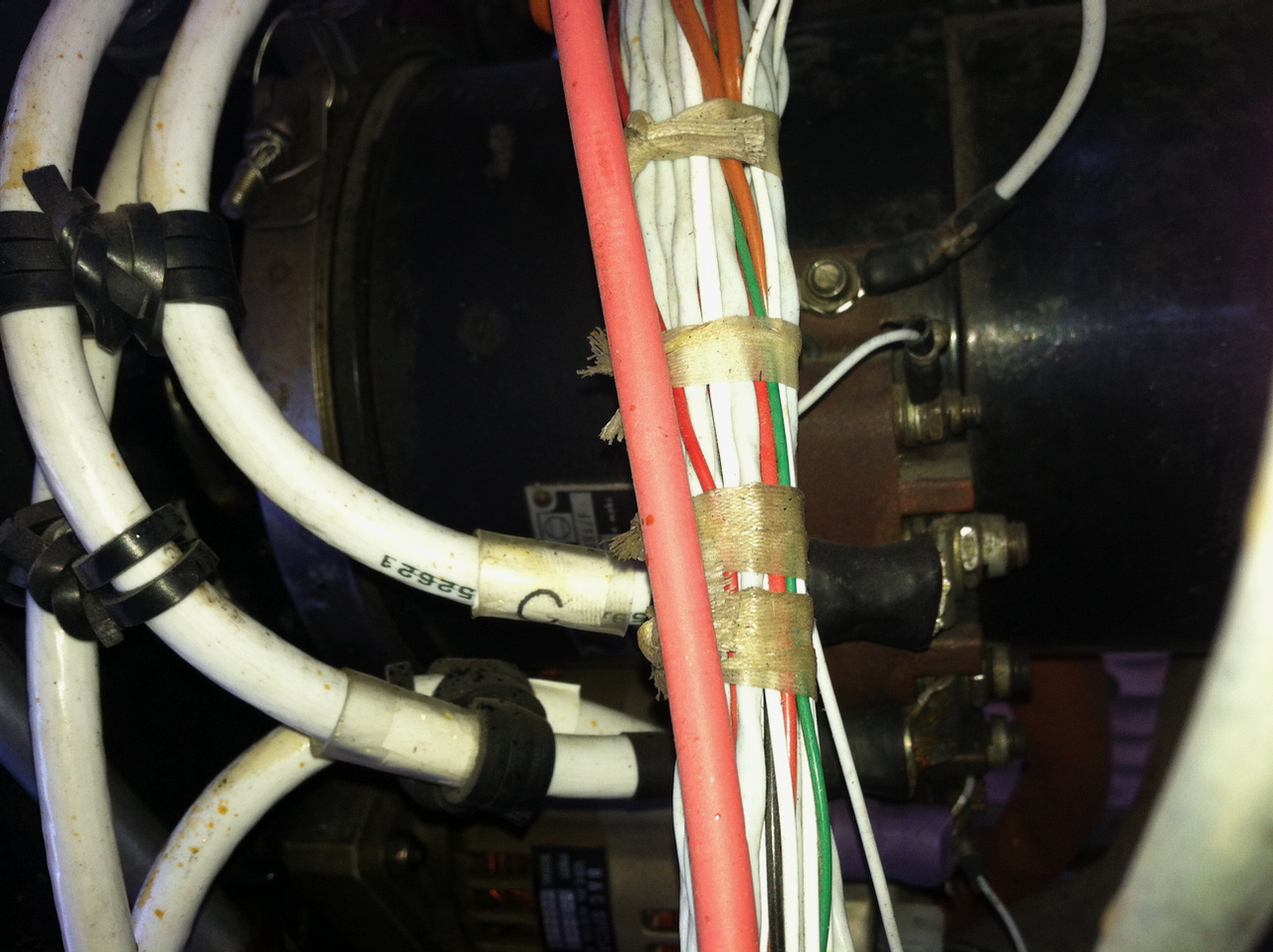

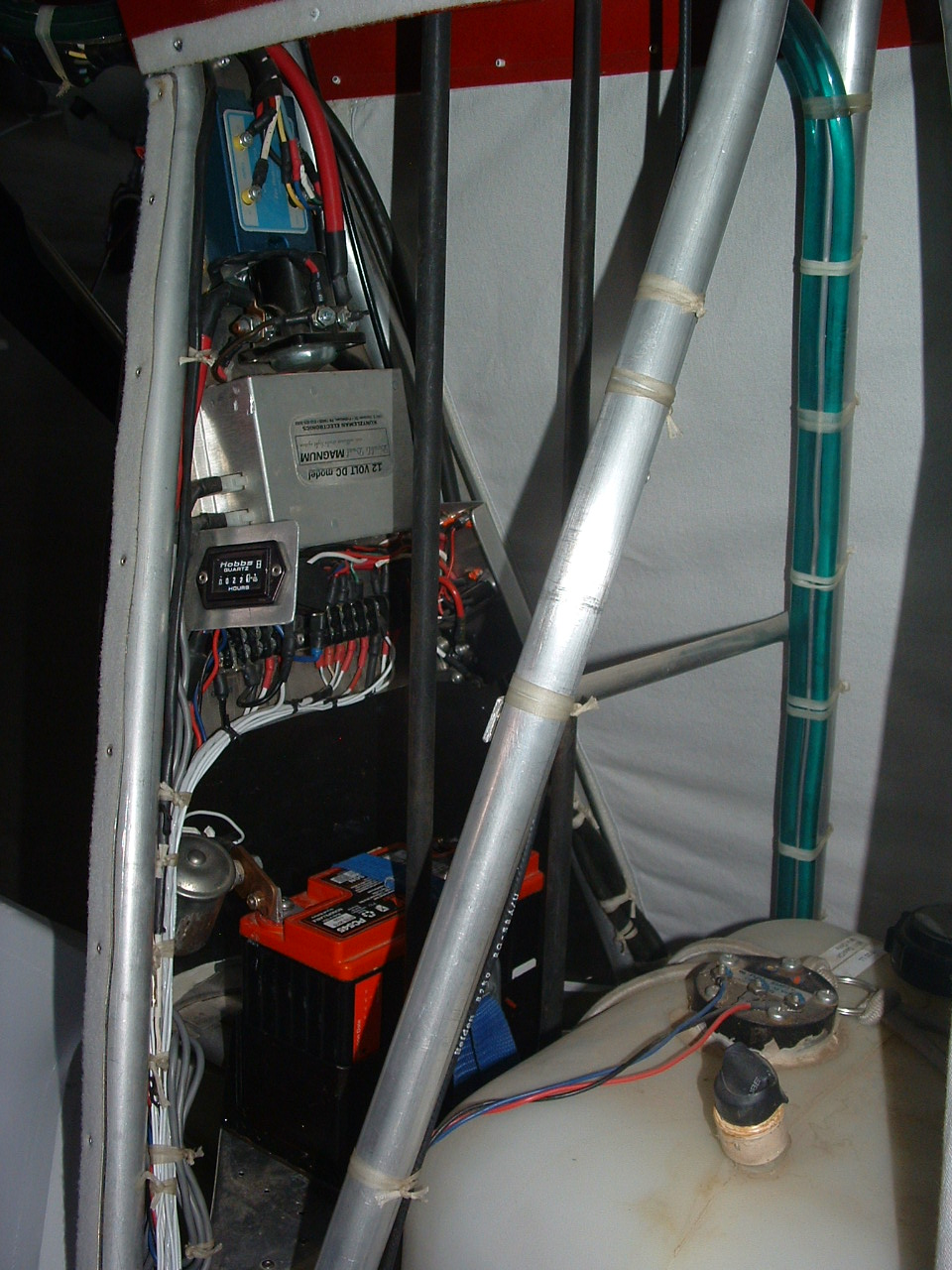

Wire Harnessing

| Tie Wraps | |

|

|

| Cheap Tie Wraps Notice the sharp edges |

Mil-Spec Tie Wraps Smooth surface against the wires. |

Yep, those that are approved for aerospace because they don't have a sharp edges.

When I saw that I suggested to him that he take one of them off and have a look underneath.

There were shallow cuts under the tie wrap, just short of damaging the wire insulation.

So he removed all of them and used harness cording and KoroSeal, which I showed him how to use.

| Better Alternatives | |

|

|

| Lacing Cord |

KoroSeal |

This was the way things were done before tie wraps. Tie wraps are fast, but they do present come problems when bundling wire.

Under "Best Practises" you shouldn't tie-wrap wires in a bundle, then add more wires and use another tie-wrap. All the existing tie-wraps should be removed so you only have one set holding the harness together and not pinching any wires. You can however, if you use lacing cord.

Testimonials

My roof air conditioner/heat pump is about 25 years old, and had been hit by lightning two summers in a row while we were up north.

Working with the AC guy was a nightmare. After presenting me with a huge bill, I then asked if he tested the system.

"Yep all is well," was the reply," it's producing cool air. "

"Well how about the heat side, did you test it ?", I asked.

"Well no, " he said.

Reluctantly he tested the heat side and it failed, so back up on the ladder he went. Then this well trained always on the cell phone getting help guy, then informed me I needed a new circuit board, which of course he didn't have with him. It was finally fixed after a week or so and at this point I decided to do things myself.

I looked at the bill, circuit board $250.00, new 40 Amp relay $95.00, starting capacitor, $50.00. Went to Amazon to price them. New circuit board $47.50, relay $11.18 starting capacitor $29.00

After a few months I decided to check it myself, so I got up on the roof opened it up and wow what a mess. One capacitor was taped to the old capacitor and simply taped hanging on the wires. I also found that all the factory terminals were corroded, as they were done with plain old hardware store stuff. The wiring from the factory was a huge bundle of wires all looped and tied up together. Figured they made a one size fits all units harness. Then I decided to replace the relay, starter capacitor and circuit board and re-wire it using the methods described above.

I shortened all the wires and redressed them properly, and soldered on all new terminals.

After servicing, the unit has never worked as good. When the compressor came on it used to make a heck of a banging noise; starved for starting current no doubt. Now we can hardly hear it when it starts and runs.

I helped an owner wire a Turbo Lancair and I wired up with the method I described above. When the test pilot arrived for the first flight and took it straight up into the air out of sight, I was sure glad I knew all the connections were done correctly, soldered.